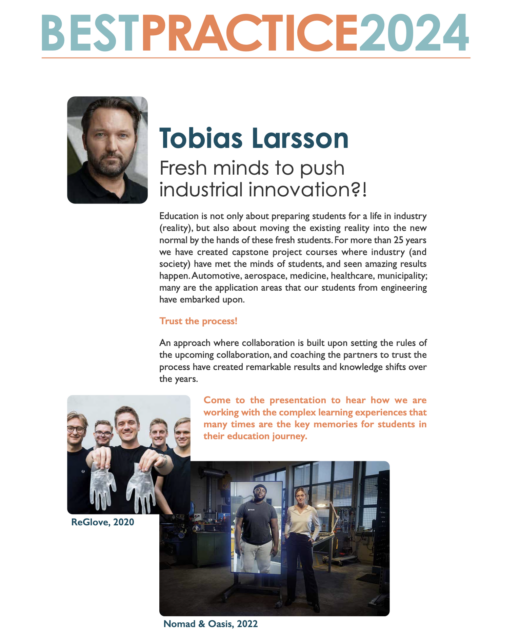

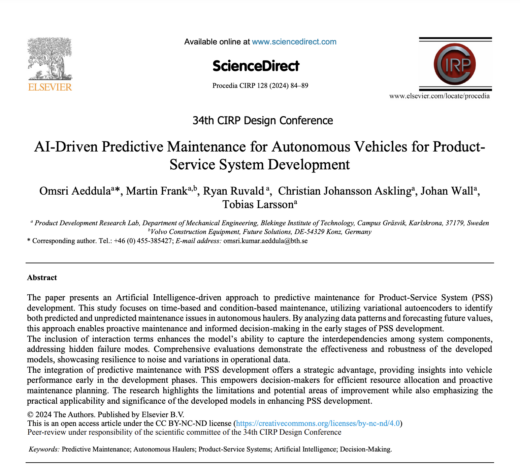

Efficient Innovation Capability | 2024-2027

Project within joint BTH / Region Blekinge 50 MSEK initiative Innovation capability is at the core if you want to be able to rapidly adopt to new situations as anorganisation and to constantly improve your operation. This project will support an organisations’need to address upcoming challenges/problems (external and internal) and...