Research paper published in Concurrent Engineering (ISI Journal)

Abstract

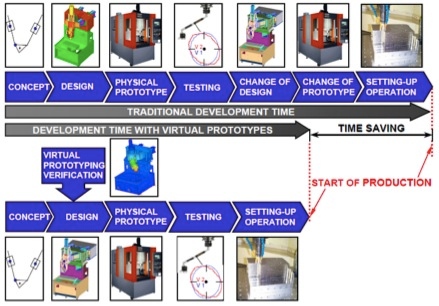

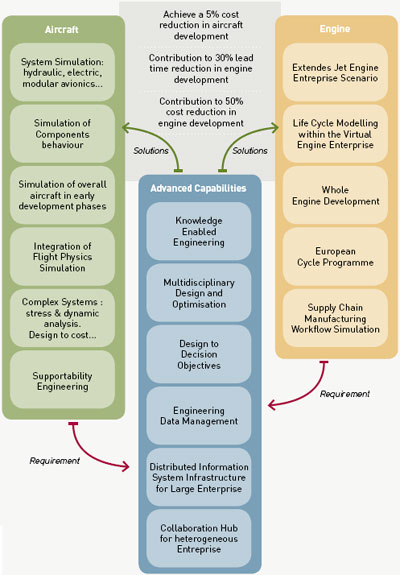

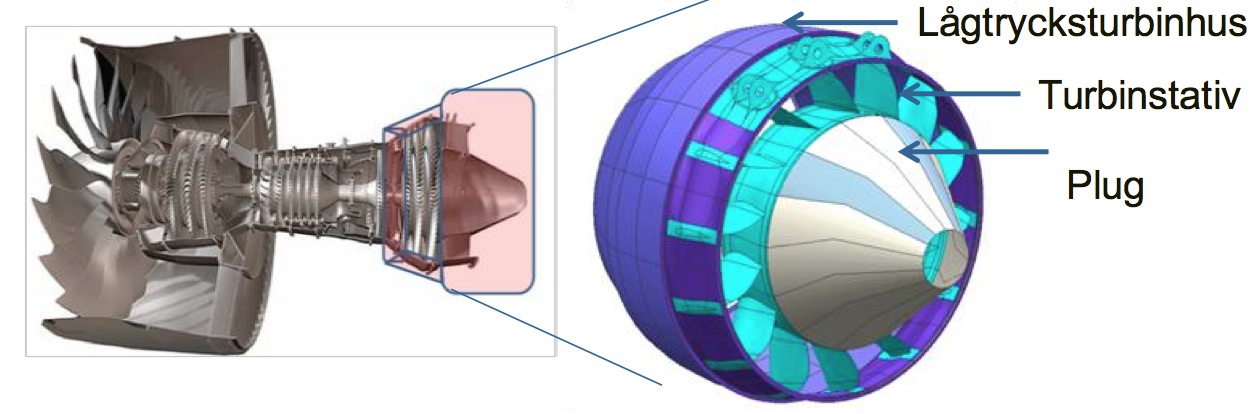

Novel rotating machinery design concepts and architectures are being explored to reduce mass, energy consumption, manufacturing costs, and environmental impact while increasing performance. As component manufacturers supply parts to original equipment manufacturers, it is desirable to design the components using a systems approach so that they are optimized for system-level performance. To accomplish that, suppliers must be able to model and predict the behavior of the whole machinery. Traditional computer-aided design/computer-aided engineering master-modeling approaches enable manual changes to be propagated to linked models. Novel knowledge-based master-modeling approaches enable automated coordination of multidisciplinary analyses. In this article, we present a specific implementation of such a knowledge-based master-modeling approach that facilitates multidisciplinary design optimization of rotating machinery. The master-model (MM) approach promotes the existence of a single governing version of the product definition as well as operating scenarios. Rules, scripts, and macros link the MM to domain-specific models. A simple yet illustrative industry application is presented, where rotor-dynamics and displacement analyses are performed to evaluate relocation alternatives for the rear bearing position of a rotating machinery under a ‘fan-blade-off’ load case.

Keywords

- Rotating machinery, knowledge-based engineering, master-models, multidisciplinary analysis and design optimization.

Reference

- Sandberg, M., I. Tyapin, M. Kokkolaras, O. Isaksson, J-O. Aidanpää, T. Larsson (2011). A Knowledge-based Master-model Approach with Application to Rotating Machinery Design. Concurrent Engineering 1063293X11424511, December 2011, vol. 19, no. 4, pp. 295-305.

- Doi:10.1177/1063293X11424511.

- Web page: http://cer.sagepub.com/content/19/4/295.abstract

Download paper

Tag cloud of paper