Concluding remarks

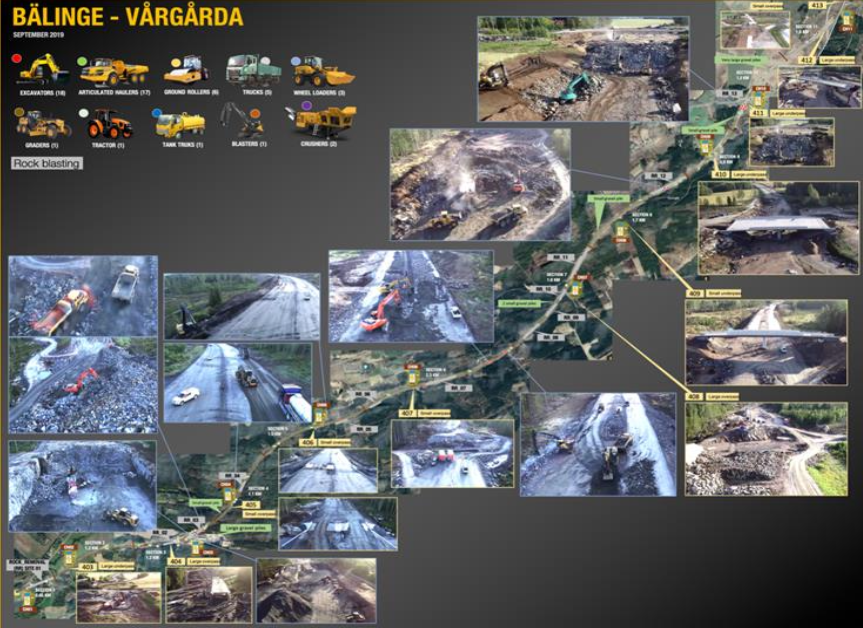

This feasibility study, which was carried out in close collaboration between Volvo Construction Equipment, Lund University and Blekinge University of Technology, has investigated the conditions for carrying out major infrastructure projects emission- and fossil-free. Furthermore, it has also been investigated whether a decision support, which can operate throughout the value chain, customer, contractor and machine/system supplier, is possible to develop. In collaboration with the Swedish Transport Administration and PEAB, the E20-Vårgårda road section was chosen to constitute the case study in the project. Although the caustic analysis has been performed with respect to other sites and applications, the emphasis in this feasibility study will relate to the Vårgårda case. Good and relevant input data from the Swedish Transport Administration and the executing contractor, put in the context of further visited sites, formed the basis for the modeling work.

Model building, simulation and calculations were divided into three parts; Development of model- driven decision support, Modeling of energy supply systems and Cost modeling at a complete site/system level. Results from the project indicate that it is possible to develop a decision support that can work throughout the value chain, however, the three parts from the pre-study should in a continuation project be incorporated into a seamless tool. The analysis in the project also shows that it should be entirely possible to carry out a major infrastructure project fossil- and emission-free. This is within the framework of what the analysis covers, which are work machines in variants that Volvo manufactures and its energy needs. The results further indicate that a battery-electric solution is preferable from a system efficiency point of view, they prove to be the most efficient system. The big challenge with battery-electric operation is the energy distribution, where the project states that there are different conditions depending on how the system is built, with included components such as infrastructure and machines and gives suggestions on solving this challenge given the different boundary conditions. The collaboration in the project has worked very well, communication with the Swedish Transport Administration, contractor, machine manufacturer and university has enabled an analysis, and synthesis, which neither of the parties would be able to achieve individually.

Research publications (so far)

- Bertoni, M., A. Bertoni, (2022), Designing solutions with the product-service systems digital twin: What is now and what is next?, Computers in Industry, Volume 138, https://doi.org/10.1016/j.compind.2022.103629.

Original project description

The goal is to demonstrate technology solutions to be able to operate larger infrastructure construction 100% emission-free by electrifying participating mobile machines. The solution will probably involve process changes and part of the project is to investigate how these can be realized at system level. This includes, in addition to investigating which solutions are suitable at machine level (new machine concepts adapted to the changed processes, as well as associated charging infrastructure), also the logistics to and from the site, which is now expanded from pure material transport to also include energy transport. An additional question will be what level of automation that will be needed to make the system not only environmentally but also economically sustainable over its life cycle. In a fully electrified solution, part of a process change could be to vary the construction rate according to the available electrical power. Here, input is needed from both customers, such as the Swedish Transport Administration, and construction companies, such as Skanska, NCC, Peab, etc., if this is possible from a societal perspective and what the financial consequences will be from such a variable construction.

The project is a feasibility study to demonstrate the capacity to carry out a fossil- and emission-free infrastructure construction. In a follow-up project, which would be a full- scale demonstration project, other actors, such as the construction company and any energy supplier, will be added as partners in the project.

PROJECT INFORMATION

BTH project leader: Professor Tobias Larsson

Time span: 20200801-20210731 (12 months)

Budget: 2 100 000 SEK (Swedish Transport Administration / Trafikverket)

Partners:

- Blekinge Institute of Technology

- Lund University

- Volvo Construction Equipment

- Swedish Transport Administration