2010-01: The divisions of Functional Product Development, Experimental Mechanics, and Mathemathics have gotten hypothesis testing from VINNOVA.

SUMMARY

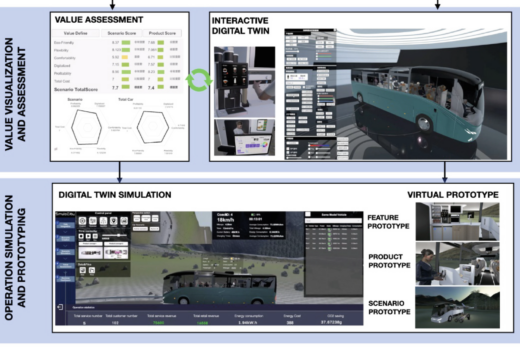

The hypothesis in this project is that it is possible to perform a quantitative evaluation of predefined attributes for a physical product in a manufacturing process in less than one second.

Today essentially all product attributes are controlled off-line which limits the flexibility and availability of a manufacturing process. But all essential attributes are normally stored on virtual form as a CAE model together with their tolerances. The bottle-neck is to be able to control them. Holography is a highly sensitive imaging modality that has become feasible due to recent developments within Photonics and IT. Combining holographic images with the virtual master through a rapid match of essential attributes will make possible an all-item control in the manufacturing process. In this project the objective is to take the essential step to couple the geometry of the physical object with the virtual.

- Tobias Larsson (FPD), Mikael Sjödahl (Experimental Mechanics)

UPDATE! 20100928, first experimental setup of Holopro

Lasrar för beröringsfri mätning av prylar med nanoprecision på under sekunden inkluderat matematisk beräkning och matchning av geometri mot utfall. Sällan vår forskning är fysisk men nu jäklar