National Aviation Engineering Research Programme

Project: V4202 Whole Engine Modelling

2007-2009 (finalized)

PROJECT SUMMARY

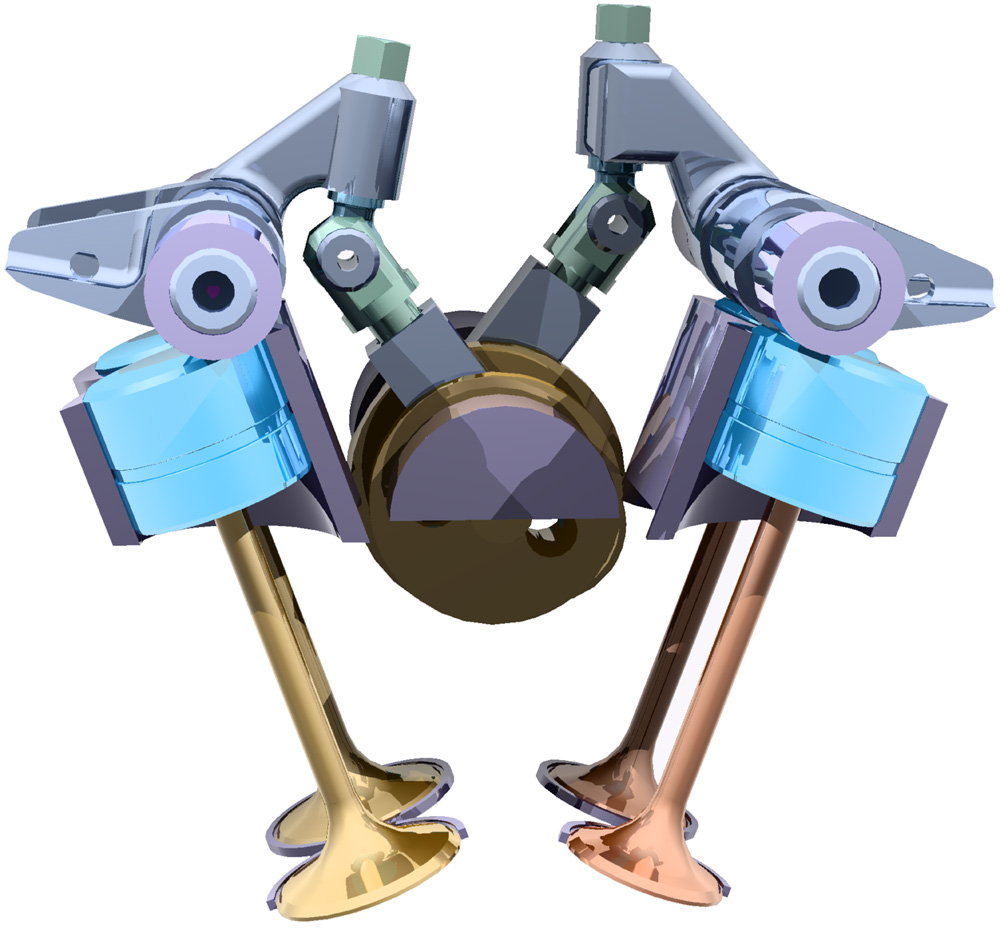

When it comes to mechanical properties, the continuous drive to reduce the weight that the engine system needs to be optimized even from a mechanical perspective. Companies with a main role to develop engine components and sub-systems hence need the capacity and knowledge to perform the engineering work that so far been done by the system integrator.

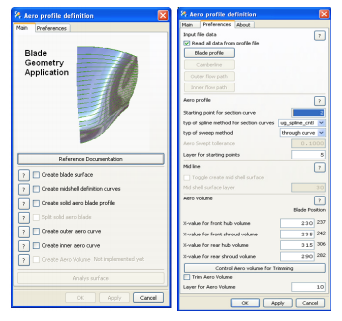

A model based approach is preferred and integration between different CAE tools and methodology for how to coordinate the modelling and simulation environment is an important part to make the approach work.

The purpose is to develop the ability to understand, model and simulate behaviour of new and existing engine configurations from a mechanical perspective. A very important part of the project is to analyze how the components work together and how this affects the final mechanical performance of the engine.

PROJECT INFORMATION

Role: Project applicant and supervisor

Type: Research

Keywords: Dynamics, Functional Products, Knowledge Enabled Engineering, Solid Mechanics, Material Mechanics

Application area: Aeronautics and Space

Time frame: 2007-2009

Funding: 4 MSEK

Research unit: Luleå University of Technology

Partners: Volvo Aero AB, VINNOVA

PUBLICATIONS

- A master-model approach to whole jet engine analysis and design optimization